Currently viewing

Menu

Intergranular Corrosion (IGC)

Intergranular Corrosion - preferential corrosion at or adjacent to the grain boundaries of a metal or alloy. [1]

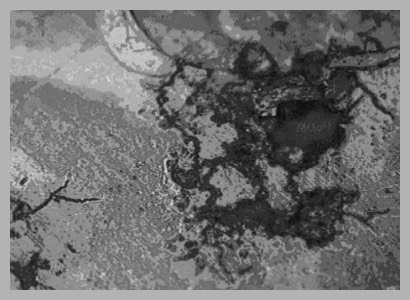

IGC of an Aluminum Alloy

in the Vicinity of a Pit

IGC of an Aluminum Alloy in the Vicinity of a Pit

Figure: T. Monetta, M. Montuori,

A. Squillace, F. Bellucci and D. B. Mitton

Advanced Materials Research

Vol. 38, p. 285 (2008).

©Trans Tech Publications

The classic case of Intergranular Corrosion (IGC) involves the sensitization of austenitic stainless steel. When certain stainless steels are exposed to the correct temperature range, Chromium (Cr) from the bulk alloy can move to the grain boundaries and form Chromium Carbides. This results in a Chromium Depleted Zone adjacent to the Grain Boundary. As a result, this zone is less corrosion resistant than the bulk alloy. The chromium depleted region is essentially no longer a "stainless" steel, and tends to corrode preferentially. An additional complication is the presence of a small anode and large cathode. This area ratio accelerates degradation within the chromium depleted region.

The mechanism described above is not the only mechanism for Intergranular Corrosion - grain boundaries tend to corrode preferentially. In the case of aluminum alloys, exfoliation may develop. This is a particular form of IGC.

The mechanism described above is not the only mechanism for Intergranular Corrosion - grain boundaries tend to corrode preferentially. In the case of aluminum alloys, exfoliation may develop. This is a particular form of IGC.

[1] NACE/ASTM G193-10b Standard Terminology and Acronyms Relating to Corrosion, 2010. All rights reserved by NACE. (Reprinted with Permission)

Currently viewing

Page last updated: 12/16/23