Currently viewing

Menu

Galvanic Corrosion

Galvanic Corrosion - accelerated corrosion of a metal because of an electrical contact with a more noble metal or non-metallic conductor in a corrosive electrolyte. [1]

Schematic Representation

of Galvanic Corrosion

Galvanic Corrosion may also be termed Bimetallic Corrosion.

If two different metals are connected in an environment that can result in corrosion, the corrosion of one may accelerate and the corrosion of the other may decrease.

If the two metals are not connected, each is corroding at an individual and specific rate.

Once connected, the corrosion potential of each individual metal will be polarized to the potential of the couple. When this happens, the potential of one of the metals will be polarized in the anodic direction - thus increasing corrosion of that metal. Simultaneously, the other metal will be cathodically polarized and the rate of degradation of that metal will decrease.

Diagram 1 and Diagram 2 below present galvanic corrosion from an electrochemical perspective.

If two different metals are connected in an environment that can result in corrosion, the corrosion of one may accelerate and the corrosion of the other may decrease.

If the two metals are not connected, each is corroding at an individual and specific rate.

Once connected, the corrosion potential of each individual metal will be polarized to the potential of the couple. When this happens, the potential of one of the metals will be polarized in the anodic direction - thus increasing corrosion of that metal. Simultaneously, the other metal will be cathodically polarized and the rate of degradation of that metal will decrease.

Diagram 1 and Diagram 2 below present galvanic corrosion from an electrochemical perspective.

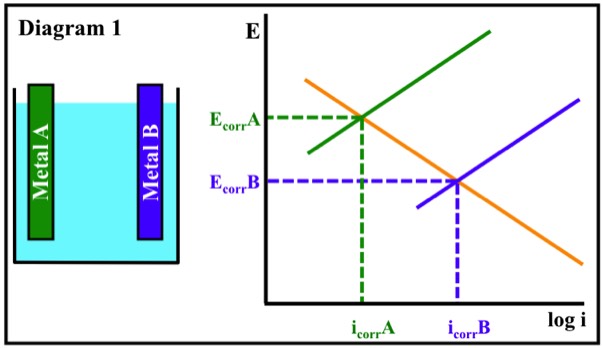

Diagram 1: From an Electrochemical Perspective - If the two metals are not electrically connected, each is corroding at an individual (and specific) rate.

Metal A is at a potential represented by the value associated with EcorrA - and is corroding at a rate represented by the current density associated with icorrA.

Metal B is at a potential represented by the value associated with EcorrB - and is corroding at a rate represented by the current density associated with icorrB.

The corrosion rate of Metal A is substantially lower than the corrosion rate of Metal B.

Metal A is at a potential represented by the value associated with EcorrA - and is corroding at a rate represented by the current density associated with icorrA.

Metal B is at a potential represented by the value associated with EcorrB - and is corroding at a rate represented by the current density associated with icorrB.

The corrosion rate of Metal A is substantially lower than the corrosion rate of Metal B.

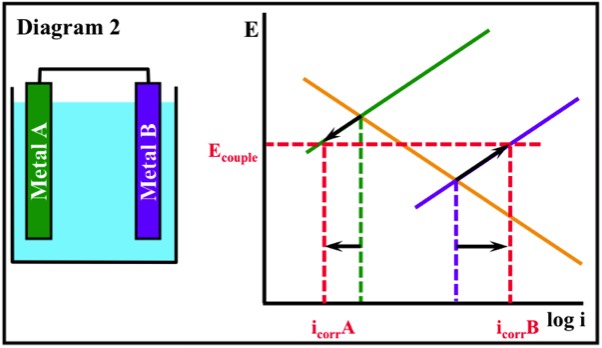

Diagram 2: From an Electrochemical Perspective - The situation changes when an electrical connection is established between Metal A and Metal B. When this happens, the corrosion potential of each individual metal will be polarized to the potential of the couple (Ecouple).

Metal A will be polarized in the cathodic direction, and the rate of corrosion will decrease to the value shown by icorrA.

Metal B will be polarized in the anodic direction, and the rate of corrosion will increase to the value shown by icorrB.

Metal A will be polarized in the cathodic direction, and the rate of corrosion will decrease to the value shown by icorrA.

Metal B will be polarized in the anodic direction, and the rate of corrosion will increase to the value shown by icorrB.

A number of criteria must be considered during the process of selecting materials, such as: Availability - Cost - Fabricability - Appearance - Corrosion Resistance, etc.

Design engineers select materials based on strength - or other important properties - without recognizing the consequences of joining dissimilar metals. This practice can result in unanticipated failures, as corrosion is frequently only considered after a failure has occurred.

A complicating factor during Galvanic Corrosion is the possibility that the polarity of the couple can change under certain circumstances. In some cases, the anode can become the cathode - and the cathode can become the anode. This has been documented in the case of iron-zinc couples, which can change polarity above 60oC. This type of behavior can give rise to unanticipated problems.

While Galvanic Corrosion can increase degradation, it is also the principle behind Cathodic Protection (CP) using a sacrificial anode. Cathodic Protection is commonly employed to protect industrial structures from corrosion.

Design engineers select materials based on strength - or other important properties - without recognizing the consequences of joining dissimilar metals. This practice can result in unanticipated failures, as corrosion is frequently only considered after a failure has occurred.

A complicating factor during Galvanic Corrosion is the possibility that the polarity of the couple can change under certain circumstances. In some cases, the anode can become the cathode - and the cathode can become the anode. This has been documented in the case of iron-zinc couples, which can change polarity above 60oC. This type of behavior can give rise to unanticipated problems.

While Galvanic Corrosion can increase degradation, it is also the principle behind Cathodic Protection (CP) using a sacrificial anode. Cathodic Protection is commonly employed to protect industrial structures from corrosion.

[1] NACE/ASTM G193-10b Standard Terminology and Acronyms Relating to Corrosion, 2010. All rights reserved by NACE. (Reprinted with Permission)

Currently viewing

Page last updated: 3/4/25